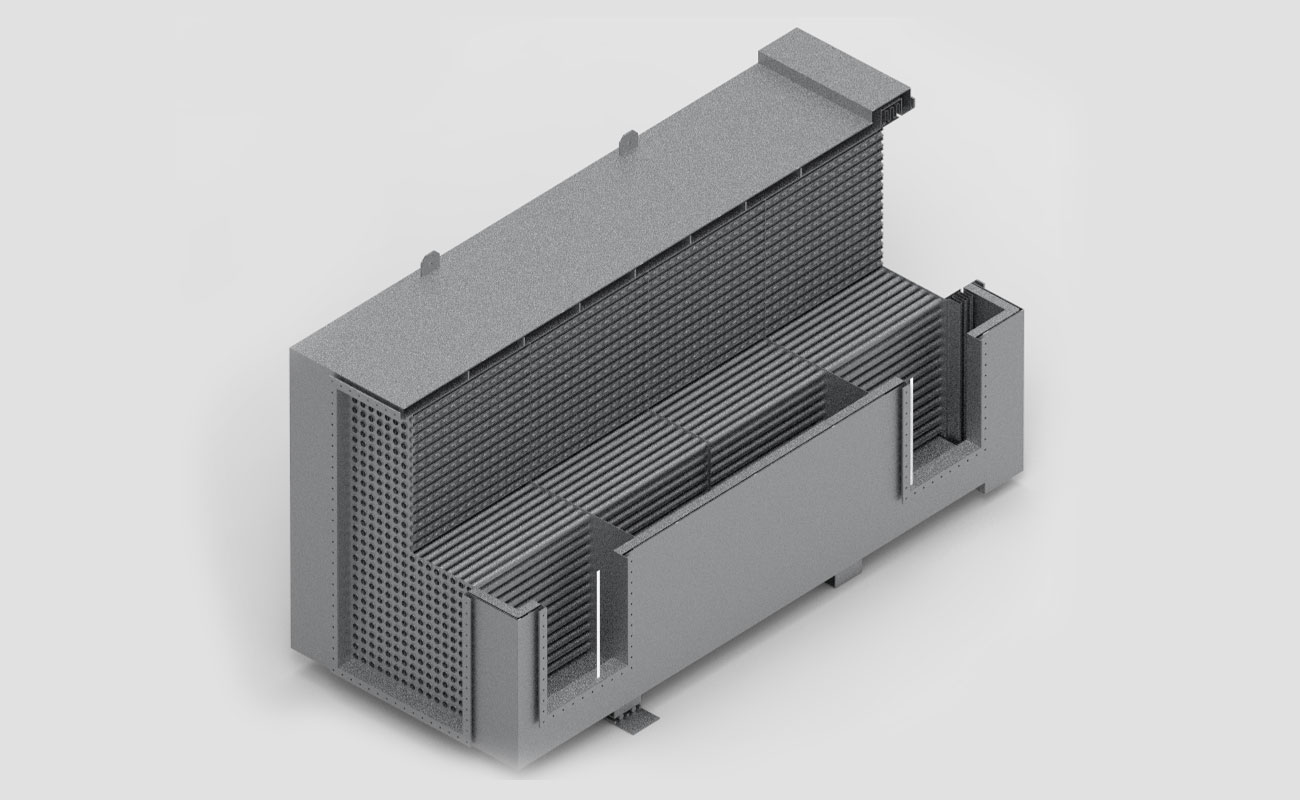

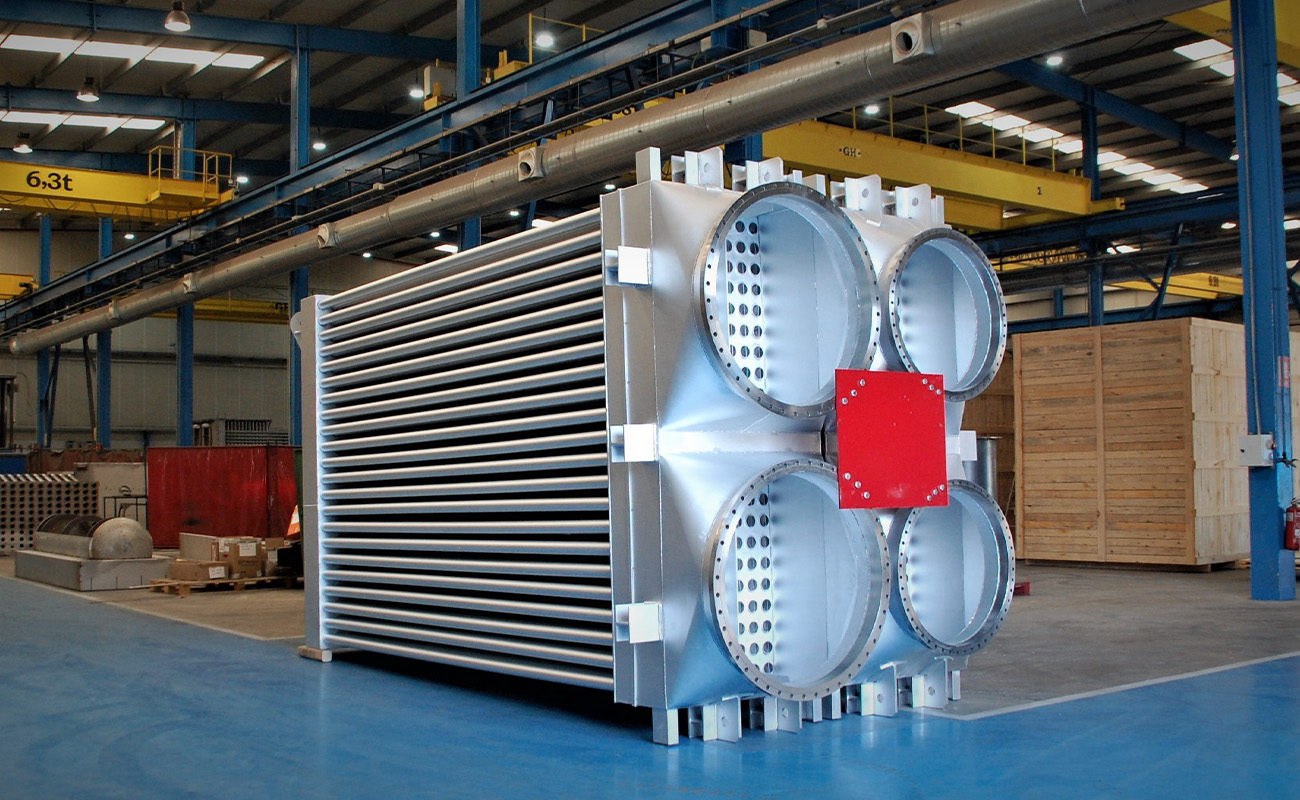

Recuperators for DRI plants

Design and manufacture in accordance with American / European regulations

Gas temperature

0

ºC

Air temperature

0

ºC

Feed temperature gas

0

ºC

At Kalfrisa we offer:

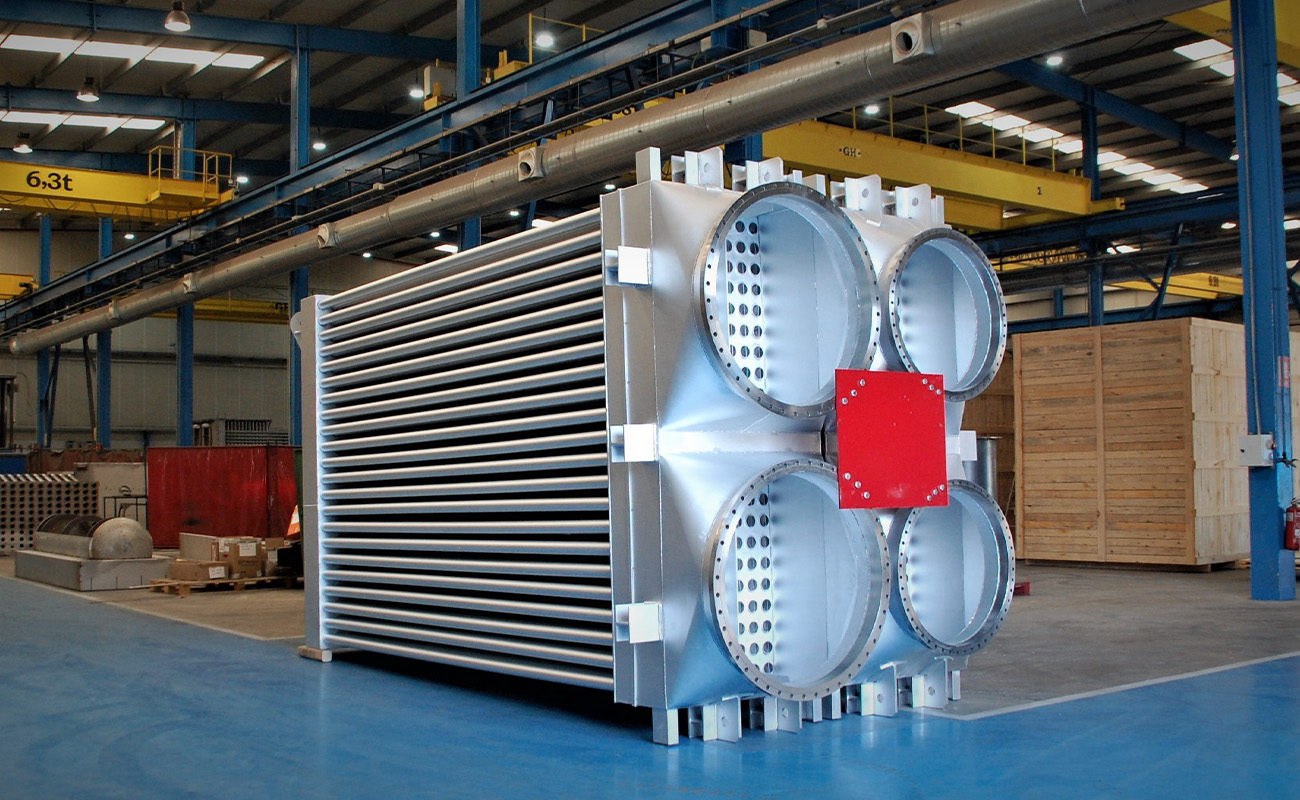

- Design and manufacture of complete heat recovery systems for new direct reduced iron (DRI) plants.

- Design and manufacture of complete heat recovery systems for existing facilities which require increased production.

- Supply of spare parts in accordance with original plans or new designs.

- Advisory work for the optimisation and improvement of heat recovery systems in existing facilities.

Our scope of supply:

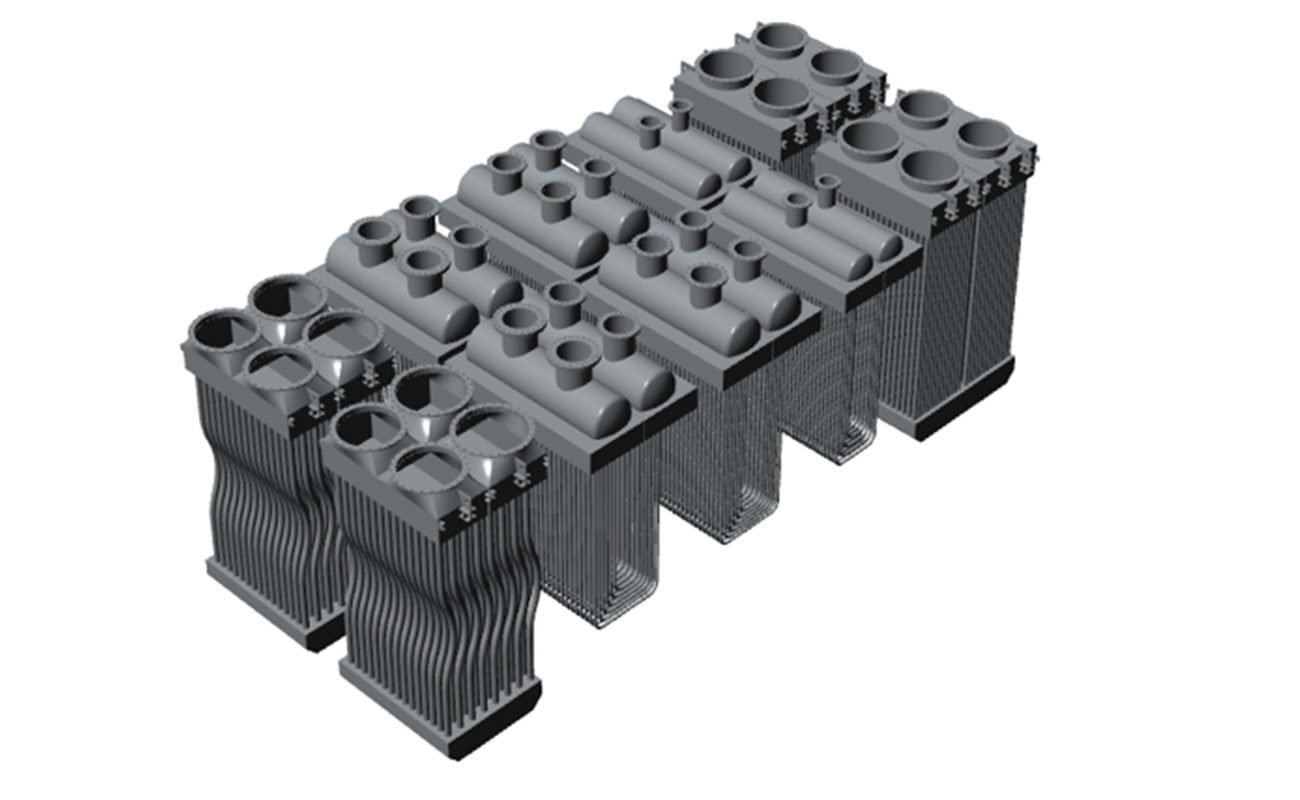

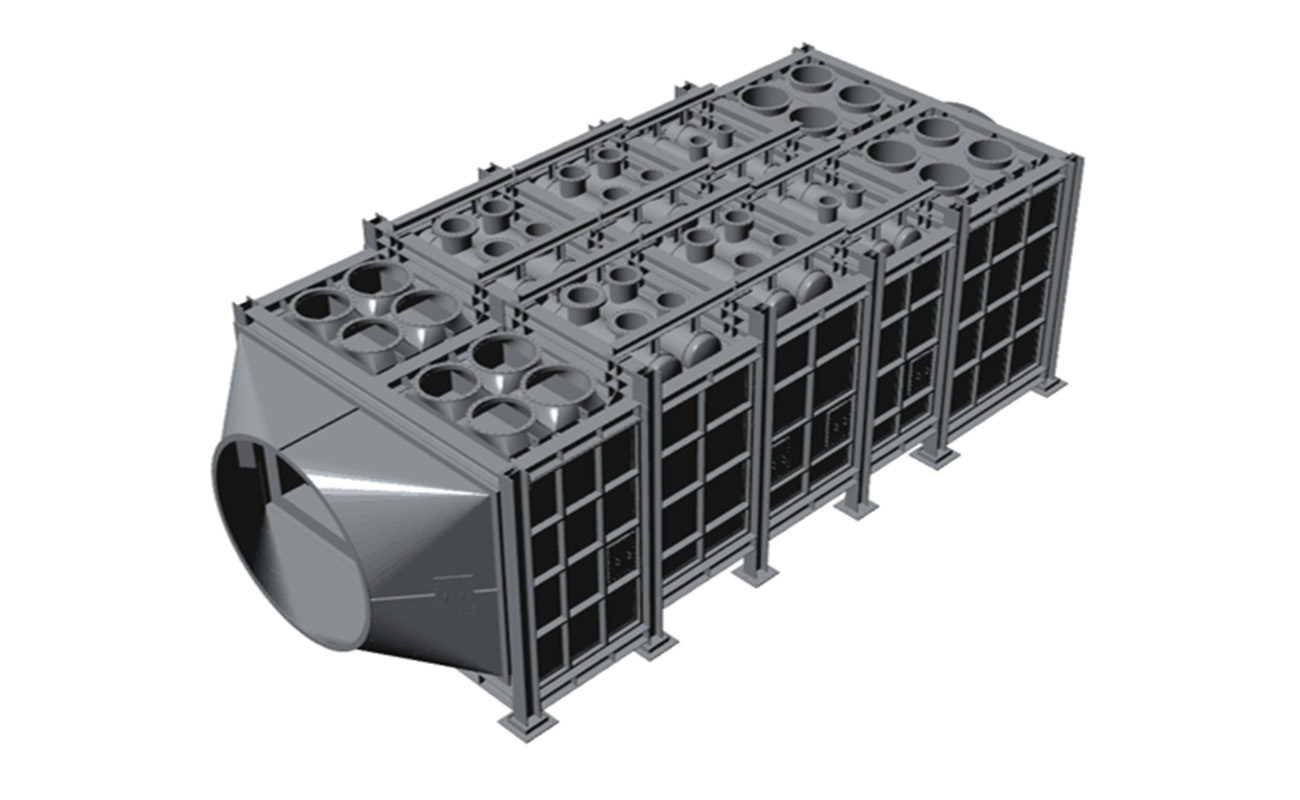

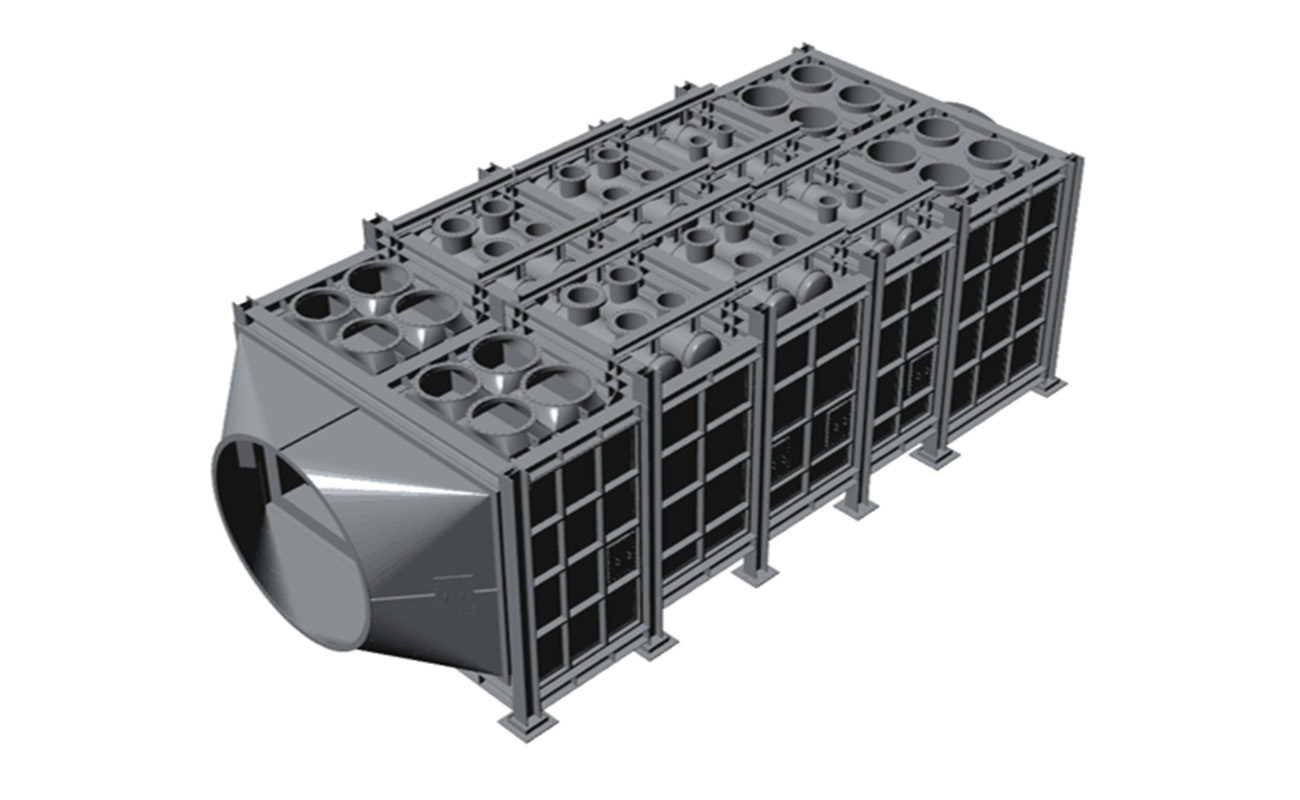

- Manufacture of heat exchangers.

- Complete detailed engineering and manufacture of the framework, refractory, piping with its insulation and support structures, including platforms.

ENERGY RECOVERY