COMPACT HEATERS

Compact heaters are highly versatil in terms of size and models, which allows them to be used in many industrial facilities.

Our compact heaters are divided into the following series:

- VTs

- VQs

- VKs

Sectors

- Food Flash drying: VKs.

- Solid foods drying: salt, pistachios, fruit, etc. : VTs

- Minerals drying: VKs

- Ceramic drying: VKs

- Automotive: VTs

- Metallic or plastic surfaces treatment: VTs & VKs

- Textil: VTs

VTs

VT air heaters are used to indirectly heat air, generally recirculated, in paint curing and drying processes. They are designed to be integrated in different input units replacing heating devices

They are suitable for drying processes in which the temperature does not exceed 300ºC and the necessary delta T (thermal jump) is under 70ºC. VT heaters are made of an isolated front panel, combustion chamber, a heat exchanger and a smoke outlet. Optionally, they can be supplied with a smoke box.

Fields of application

- Textil

- Mineral

- Ceramic

- Automotive

- Metallic and plastic surfaces treatment

Criteria for use

- Useful heating power of 30,000 up up to 1,200,000 Kcal/h.

- Air temperature increase up to 40ºC (70ºC with directional plates).

- Air outlet temperature up to 200 and 300ºC, operating with return or external air.

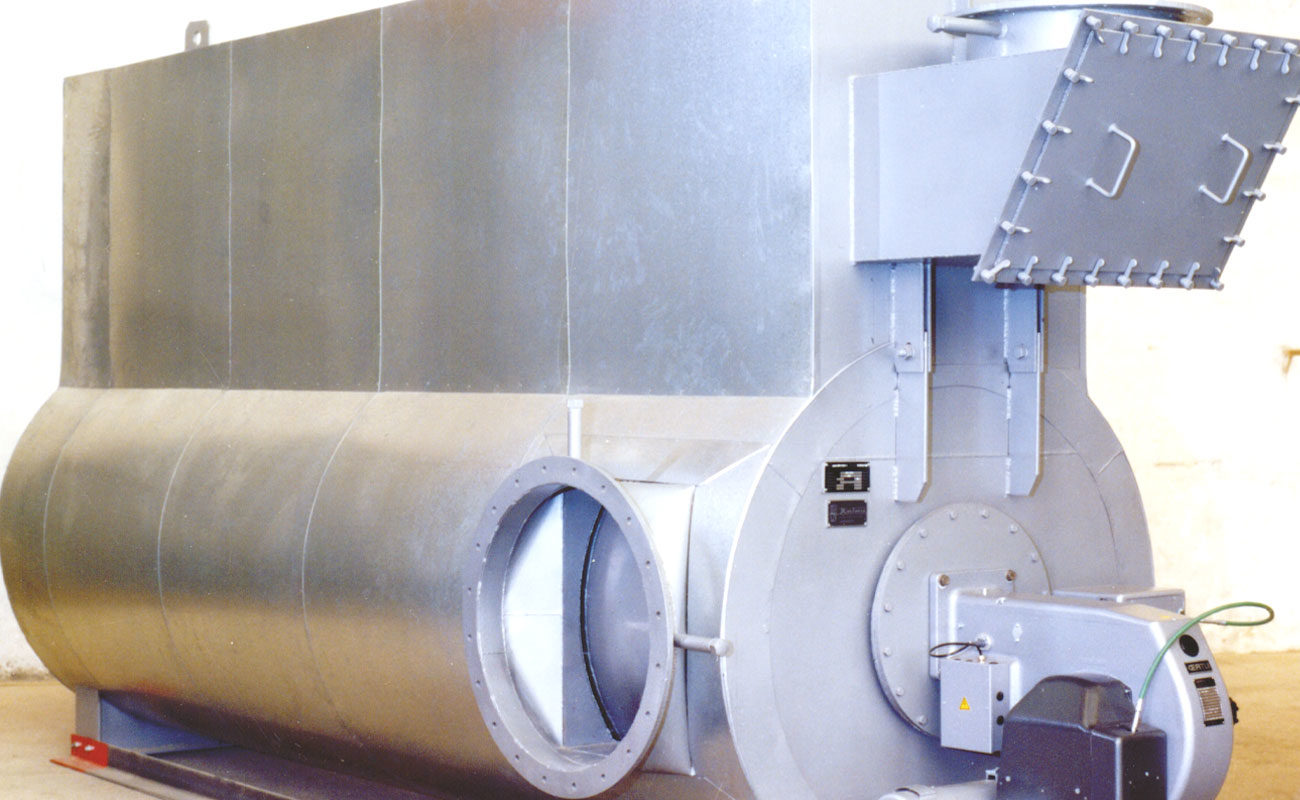

VKs

VKs are the most powerful indirect air heater for industrial processes in our range. They offer the largest delta T (thermal jump), up to 450ºC.

VK serie is manufactured as a single piece to facilitate their installation at the plant, transport and handling. These heaters are used to indirectly heat air for different processes such as flash drying for food, drying of minerals and other materials, obtaining hot air for different uses, etc.

They can be fully made of stainless steel to guarantee fulfilment of food sector requirements. They are robust devices which tolerate thermal dilations due to use of compensators well and can operate with different types of fuels. They are supplied in different positions and the position of their inlets and outlets is conveniently adapted according to the clients requirements.

VQs

VQ heaters have a similar power range than VKs, their main difference is that the heat exchange is done in just one step.

Fields of application

- Food

- Textil

- Mineral

- Ceramic

- Automtive

- Metallic and plastic surfaces treatment

- Clean hot air generation

Criteria for use

- Review table to appropriately adjust to working conditions.

Δ°C | Useful power (kW) | Working pressure (mmWG) | Working flow (Nm3/h) | Air output temperature (ºC) | |

VTs | 70 | 30-1400 | 200 | 2500-96000 | 300 |

VQs | 250 | 30-1400 | 1000 | 1000-30000 | 400 |

VKs | 450 | <1500 | <2000 | 5000-40000 | 450 |